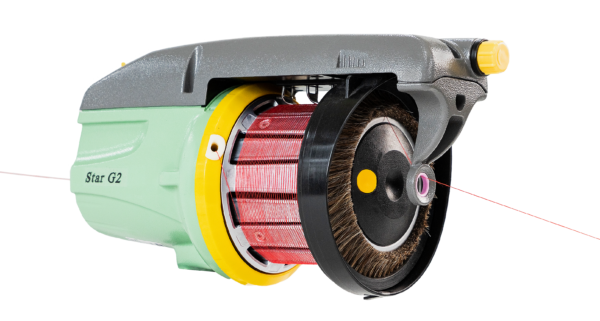

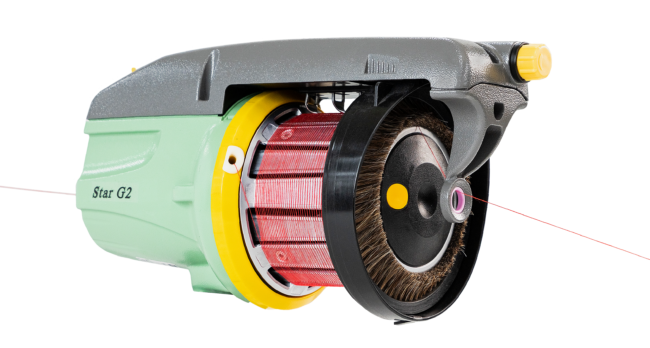

IRO Star G2

The IRO Star G2 incorporates many of the latest feeder developments into one neat package.

IRO Star G2 are designed to handle up to medium range speeds of modern weaving machines, but also as replacement on older weaving machines still in operation.

All our weft feeders are equipped with permanent magnet motors for low energy consumption combined with high performance.

Star G2 can only be fitted with brush ring as ballon control.

The components

S/Z Switch

Used to set the directions of rotation, or to activate the standby mode.

Mechanical sensor system

New improved sensor system ensures optimal tension control and includes an integrated yarn break sensor.

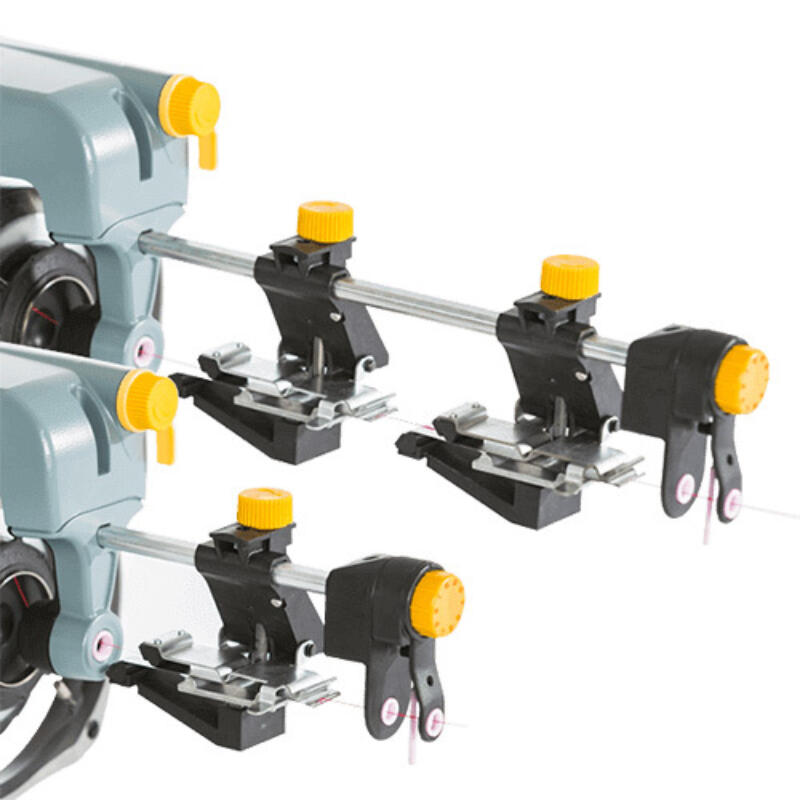

Easy balloon adjustment

Adjustable knob for easy and precise brushring adjustment - even when the feeder is running.

Separation setting

Stepless yarn separation adjustment - without the need for any tools.

Spool body

A uniquely designed, high quality, surface treated spool body gently handles a comprehensive range of yarns, providing the optimal yarn “take-off” tension, and ensuring the minimum amount of dust.

Permanent magnet motor

A powerful maintenance-free “permanent magnet motor” ensures low energy consumption, low operating temperature and high torque at all speeds.

Soft spool body seal

Prevents dust and lint penetration of the ball bearings.

| IRO Star G2 | |

|---|---|

| Maximum speed: | 1200 m/min |

| Yarn count range: | 120 – 2 Nm and 20 – 3500 dTex |

| Winding direction | ”S” and ”Z” |

| Yarn separation: | 2,2 mm |

| Sensor systems: | Mechanical |

| Spoolbody diameter: | 110 mm |

| Dimensions: | 190 mm height, 305 mm length, 150 mm width |

| Weight: | 4,7 kg |

| All basic weft feeders exist in models that cover todays range of power supply boxes, this make replacement easy for the customer. |

| File | Size | Date |

|---|---|---|

| 3 MB | 2024-09-19 | |

| 3 MB | 2024-09-19 | |

| 3 MB | 2024-09-19 | |

| 3 MB | 2024-09-19 | |

| 6 MB | 2024-09-19 |

| File | Size | Date |

|---|---|---|

| 3 MB | 2025-09-23 | |

| 3 MB | 2025-09-23 |

Submit your data and you will be contacted by one of our experts