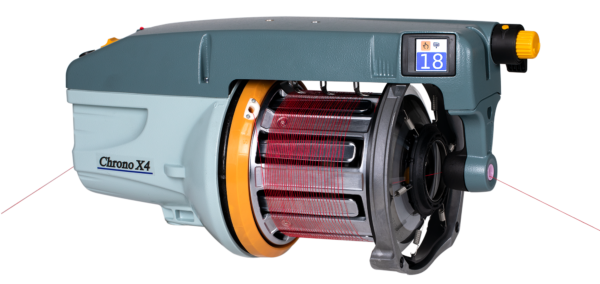

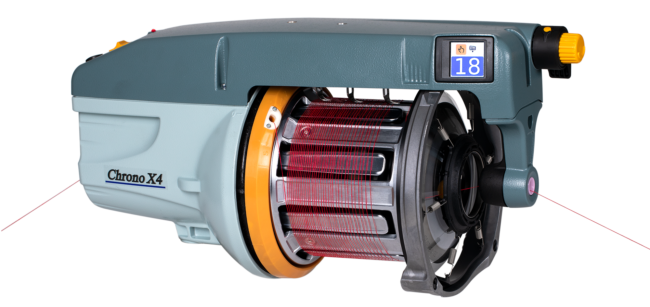

IRO Chrono X4

Meet our Generation 4, the new Chrono X4.

We are setting a new standard with Integrated display for tension setting, TED, which is available as standard on the new generation weft feeders.

The TED function is an integrated display where you can set desired tension value for the fabric production, easily viewed on the display, and includes also alarmsfor example weft yarn break.

All settings made with by the yellow knob in front of the weft feeder.

The integrated display is also compatible with our ATC Active Tension Control who will maintain tension through the full weaving cycle and proves thewell-proven design combined with new possibilities for modular build-up of the weft feeder.

With the improved accessibility for connecting powered accessories and with connection to our light-weight switch-mode power supply to maximize the energy efficient permanent magnetmotor. Along with re-designed and improved sensors complemented by an improved threading-up system.

This message is to all our customers that uses weft feeders, to feel confident that we are assisting the market for the future that lays ahead of us all.

The components

Spool body

The specially designed high quality surface treated spool body gently handles a wide range of yarns and offers the lowest yarn take-off tension and minimized dust collection.

Pneumatic treading

"Easy access" push-button system for fast "one-step treading" (through the entire feeder), or "half-treading" (from the input eyelet to the spool body).

Sensor system

Mechanical or optical sensor systems (including an integrated yarn break sensor), ensures precise yarn reserve control.

Easy balloon adjustment

Adjustable knob for easy and precise brushring adjustment - even when the feeder is running.

Permanent magnet motor

A powerful maintenance-free “permanent magnet motor” ensures low energy consumption, low operating temperature and high torque at all speeds.

S/Z Switch

Used to set the directions of rotation, or to activate the standby mode.

Separation setting

Stepless yarn separation adjustment - without the need for any tools.

| IRO Chrono X4 | |

|---|---|

| Maximum speed: | 2000 m/min |

| Yarn count range: | 120 – 0,8 Nm and 20 – 5000 dTex |

| Winding direction: | ”S” and ”Z” |

| Yarn separation: | 4 mm |

| Sensor systems: | Optical or mechanical |

| Spoolbody diameter: | 135 mm |

| Dimensions: | 220 mm height, 420 mm length, 190 mm width |

| Weight: | 8,6 kg |

| File | Size | Date |

|---|---|---|

| 3 MB | 2024-09-19 | |

| 3 MB | 2024-09-19 | |

| 6 MB | 2024-09-19 | |

| 3 MB | 2024-09-19 | |

| 3 MB | 2024-09-19 |

Submit your data and you will be contacted by one of our experts